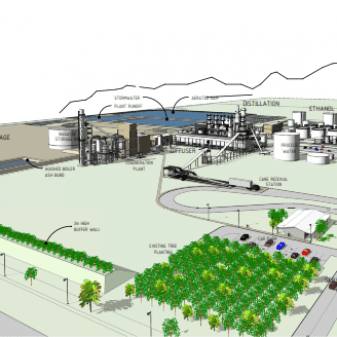

TFA is proud to have worked with Dalby Bio-Refinery Limited, Delta-T Corporation and Leighton Contractors Pty Ltd in developing the Dalby Ethanol plant.

TFA was closely involved in the preliminary site designs, costings and co-ordination of Environmental Licensing and Development Approval for the Dalby Bio-Refinery project and then performed the complete detailed design in 2008, working closely with the constructors, Leighton Contractors Pty Ltd, including conversion of US specifications for Australian compliance.

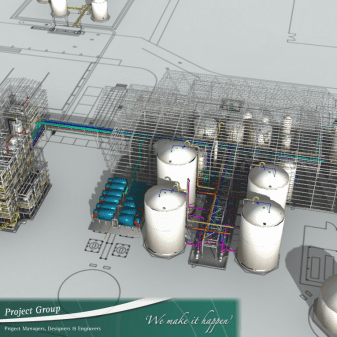

As lead designers and engineers, our scope included civil, structural, electrical, hydraulic, tank and 3D piping designs, approvals, procurement technical reviews, tender and construction documentation.

Project Scope:

- Project value $100 million

- Two grain silos and associated conveyors

- Three 1.4ML fermenters and 1.6ML Beer Well

- 16 Process Tanks

- Process Piping and 85 Pumps

- Two boilers and steam distribution

- Distillation and Dehydration Process

- Ethanol Tank Farm with four tanks

- Ethanol Tank Truck Fill Stand

- Fire Fighting Tank, Pumps, Hydrant and Sprinklers

TfA’s Role included:

- Selection of a US Technologist for the project

- Project feasibility , Basis of Design Specification and preliminary budgets

- Site layout master planning

- Front End Engineering Design

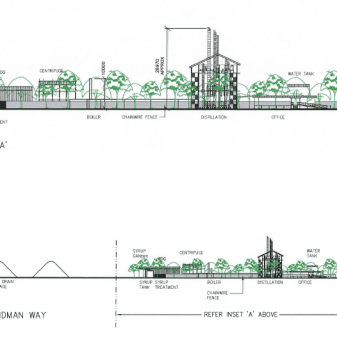

- Preparation of DA submission for project approvals

- Detailed Design Documentation

- Australianisation of Delta T technical specifications. Preparation of construction tender documentation.

- Technical review for plant equipment supply offers.

Detailed Design Deliverables

The scope for TfA’s Detailed Design Documentation included:

· Civil design

|

|

· Tank Farm Design

|

· Fire Fighting Design

|

· Mechanical / Piping Design

|

· Electrical and Instrumentation

|