The New Version of AS1940:2017 The Storage and Handling of Flammable and Combustible Liquids has now been released and is in force.

In this Industry Note, we build on the back of our previous update in July highlighting some of the more significant changes under AS1940:2017 for different types of development in the fuel industry.

Unmanned Refueling Facilities / Above-ground Storage

The last few years have seen a considerable increase in the development of unmanned truck refueling facilities across remote and regional Australia.

Traditionally, these facilities involve above-ground diesel storage in double-walled tanks often with the dispensers fitted to the front of the tank. More recently, TFA has been involved in the design of numerous facilities which seek to incorporate flammable liquid storage, often in the form of a smaller above-ground unleaded petrol tank which may include bulk load-out to fuel delivery trucks servicing a particular region.

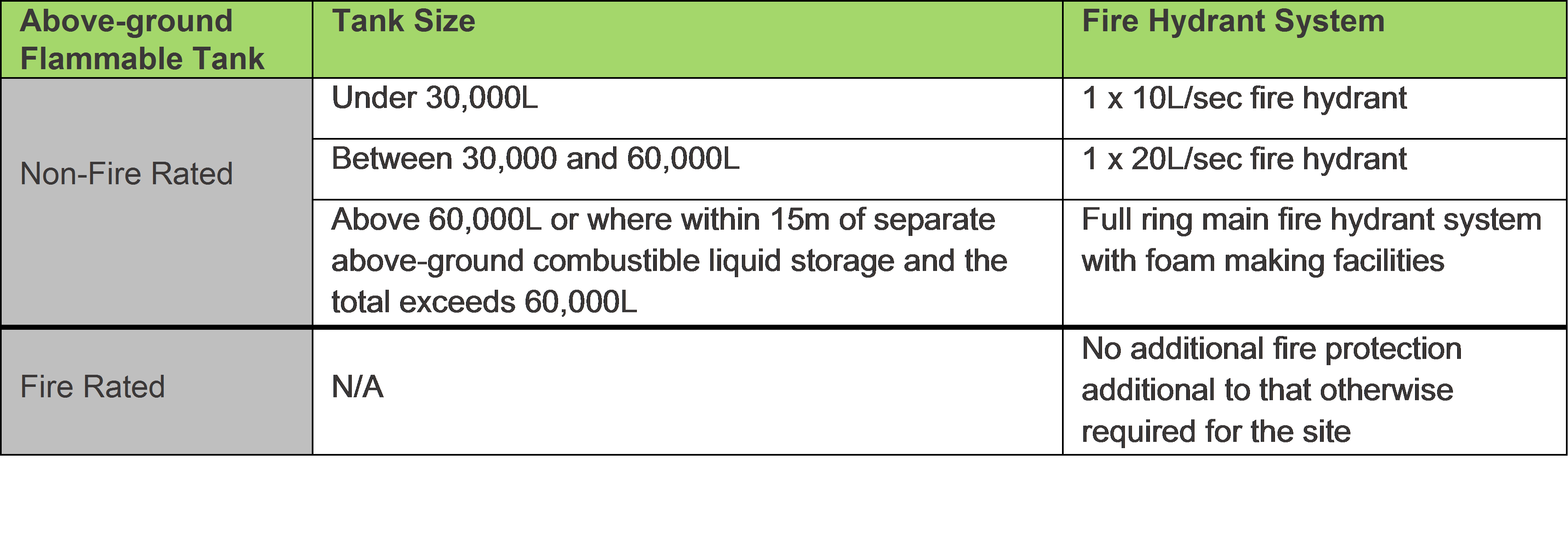

TFA has conducted an initial review of the final version of AS1940:2017 and one of the more notable impacts for refueling facilities storing above-ground flammable liquids is the potential requirement to provide a fire hydrant system on-site. The table below provides a brief snap-shot of potential requirements.

Note: a fire rated above-ground flammable tank must have an FRL of 240/240/240 and comply with UL2085 or be approved by UL or FM to the equivalent US fire rating.

The Importance of Compliant and Accredited Design

Introducing above-ground flammable storage introduces a greater level of risk to be managed on-site. The risk however can be more effectively mitigated through compliance with AS1940:2017. This reinforces the importance of designing and locating above-ground tanks in accordance with AS1940 and in ensuring the related fuel system design is appropriately accredited by a full member of the AIDGC and a registered RPEQ engineer when located within Queensland.

With over 20 years in both fuel system design and the related site layout design of fuel facilities, we pride ourselves in not only being across the changing landscape of AS1940 compliance, but also in offering our clients the appropriate RPEQ and full AIDGC accreditation in signing off compliant fuel system design. The latter, we observe, is frequently undertaken by other design consultants without appropriate engineering qualifications or full accreditation. Particularly on an unmanned site, this introduces additional risk and liability to the owner and fuel operator which they may not be aware of. In our experience, a compliant and accredited design not only assists in meeting obligations under the WHS Act 2011 in the event of an on-site incident / site audit, but also with due diligence during the sale of a facility.